Concept Design for a Tank Farm – Future-Proof Raw Material Logistics

Introduction

In many industrial plants, the pressure is increasing: rising production volumes, higher requirements for safety and sustainability, and the need to respond flexibly to new raw materials. The situation was no different in this project: the existing storage capacities had reached their limits. Switching to tank storage was hardly possible with the existing infrastructure – logistics had reached a turning point.

This is where we came in. With our expertise in plant design, safety engineering and process integration, we laid the foundation for making the site’s raw material logistics fit for the future.

Our Mission

We were commissioned to prepare the concept design for a new tank farm – as a decision-making basis for the expansion of storage capacity. The focus was not only on creating additional volume, but also on developing a holistic concept that combines safety, sustainability and efficiency.

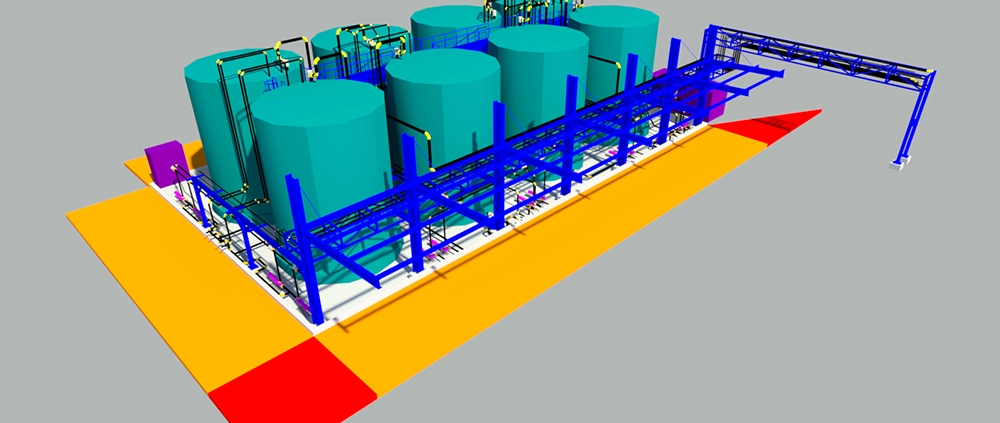

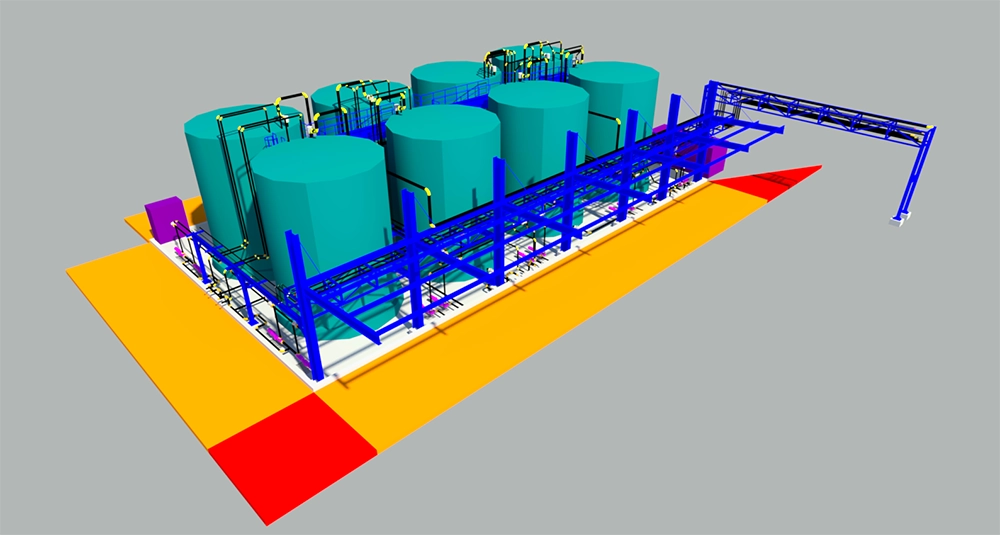

The Design in Detail

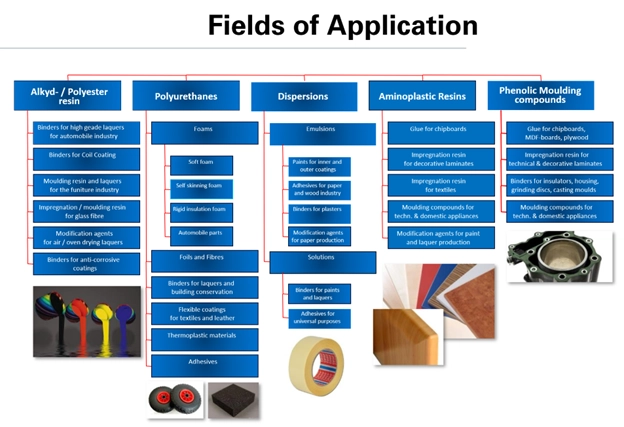

The new tank farm is modular in design and, in its final expansion stage, will comprise eight on-site fabricated tanks with a net capacity of 250 m³ each. In the first construction phase, six tanks will be erected, with two more to be added in the second stage. The tanks are designed for various raw materials used in the production of synthetic resins.

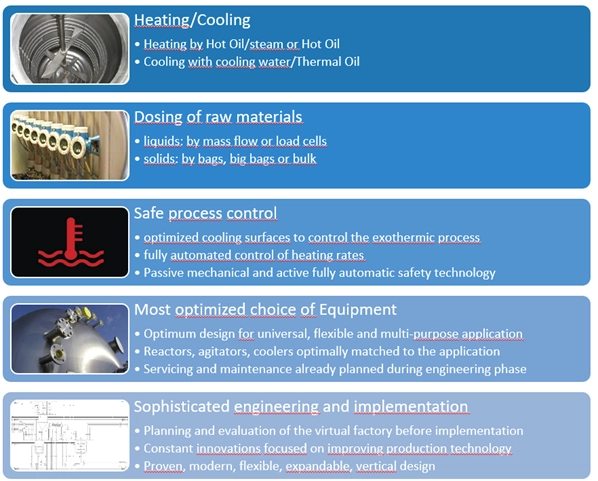

Our design focused on the following key aspects:

Explosion Protection:

All components are designed for operation in potentially explosive atmospheres (Ex zones). This ensures the highest level of safety in daily operations.

WHG-Compliant Safety Technology:

All tanks are placed in a containment basin capable of holding at least the volume of one tank. A special coating ensures that even in case of an incident, no drop can escape into the environment.

Modern Infrastructure:

Five unloading stations for tank trucks provide short routes, clear media allocation and smooth operations – even under full load.

Process Stability:

For temperature-sensitive raw materials, tanks and pipelines are equipped with heating systems to ensure constant conditions.

Sustainability:

Exhaust air streams are not released into the atmosphere but treated in a regenerative thermal oxidation unit – a clear contribution to environmental protection.

More than a tank farm

For us, this project is much more than the design of eight tanks. It is an example of the transformation of industrial logistics: from traditional raw material storage to a facility that meets the highest safety standards, protects the environment and makes the production site fit for the future.

Our contribution

Through close collaboration within our project team, we developed a concept that takes all aspects into account – from technical feasibility and process integration to safety and environmental protection.

We are proud to have laid the foundation for safe, sustainable and efficient raw material logistics with this design.